Infrastructure

Complete Flexible Packaging Solutions

Our dedication to honoring our business commitments combined with good quality products, competitive prices & services has helped us to establish Imprint Packaging in the hearts of our customers.

DESIGN & PRE-PRESS

In today’s competitive world, it is most important to make a good first impression& catch the eye of the customer when it comes to the packaging of the product. Our design team works collaboratively to give your company effective & eye-catchy designs to put your brand ahead. We are equipped with the latest software to handle files of different formats & give you the desired output. The Pre-press section takes care of the complete process of making electronically engraved, digitally color-calibrated rotogravure cylinders so that designs are printed with perfection. We have a full-fledged warehouse to take care of the cylinders of various jobs of our customers.

QUALITY & TESTING

Quality is the core of our business. Our quality control department is fully equipped to handle all necessary tests using the latest testing equipment. All incoming raw material, semi-finished & finished goods undergo thorough testing for their quality using our standard operating procedures so that a defect-free product goes out of our manufacturing premises. Our quality control team takes care of all pre-defined quality procedures at all stages of production.

PRINTING

We have two numbers high speed automatic eight color Roto Gravure ARC printing machines that can print on a wide variety of substrates. From a normal printing jobs, we can print using specialized UV curable inks with metalized finish in rich & luminous colours. The manufacturing capacity of our plant is 200 metric tons pa.

LAMINATION SOLVENT LESS AND EXTRUSION

Imprint Packaging provides the customer various options to get composite layer of pouches using variety of laminates such us PET, Foil, BOPP, Nylon, Poly, Paper, etc.ranging from 10 microns to 200 microns. We are capable to handle alumimium foil without wrinkles or any other damage. Presently we can produce 2ply & 3ply pouches, but we shall soon be adding machine to produce 4 ply pouches.

Slitting machines

A slitter, a slitting machine, or a slitter rewinder is the mechanism that performs the slitting procedure. Simply described, a slitting machine’s principal function is to convert (slit) papers, film, and foil materials so that big rolls of these materials can be sliced into smaller rolls. We, at Imprint use this slitting machine to make the packaging

Doctoring machines

The doctoring machine is ideal for recovering any sort of incorrectly built and defective printed, laminated reels with little changeover time by a single operator. We utilise this doctoring machine at Imprint for a variety of procedures, including on-line printing, inspecting various types of defects in the laminate during printing, lamination, and slitting, etc.

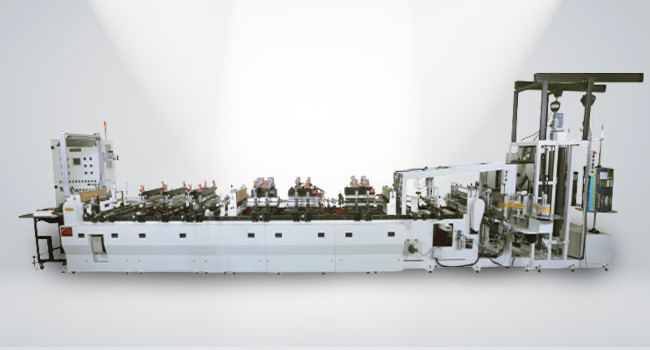

Pouch & Sack Bag Making

We have established ourselves in Indian flexible packaging industry & have produced millions of pouches in various formats such asThree Side Seal Pouch, Center Seal Pouch, Vacuum Pouch, Side Gusseted Pouch, Stand up Pouch, Zipper Pouch, Paper Pouch, etc. We can produce a pouch of big as 1100 x 1000 mm size.